Extrusion

Our state-of-the-art, 3-layer blown co-extrusion film plants are equipped with cutting-edge technology to ensure superior film performance. Key components include

- IBC (Internal Bubble Cooling): Enhances film quality by controlling the cooling process, ensuring uniform thickness and reducing defects.

- Gravimetric Dosing Systems: Accurately measure and mix raw materials, guaranteeing precise formulation and consistency in film production.

- Air Ring: Optimizes the cooling and expansion of the film bubble, contributing to uniform film thickness and excellent physical properties.

- Auto Gauge Controls: Provide real-time thickness measurements and adjustments, ensuring optimal film quality and reducing waste.

Our extrusion capabilities offer a range of film options to meet diverse needs

Clear Transparent

Achieve complete Visual Oversight with fast inspections and streamlined quality checks for effortless defect detection.

Simplify Identification and Segregation: Clear surface visibility eliminates confusion or mix-ups at the plant.

Showcase your Unique Finishes - Transparent films are ideal for coloured and structured finishes, allowing customers experience aesthetic excellence.

Black and White (B/W)

Black colour bottom gives Superior UV Shield: Unique light transmission properties safeguard the product from harsh UV radiation.

Showcase your Unique Finishes - Transparent films are ideal for coloured and structured finishes, allowing customers experience aesthetic excellence.

White Opaque

Increased Performance Reliability - Eliminated the small risk of black residue left behind when welding, and deburring.

Safety and Equilibrium: The optimal choice balancing UV stability and residue-free performance.

Metallized - Silver

Film coated with a thin layer of Aluminium - giving a glossy metallic appearance.

Uniqueness that Shines: Elevate your product's aesthetic appeal in the marketplace.

Ultimate Defence - Delivering the best barrier properties against UV radiation and moisture permeability.

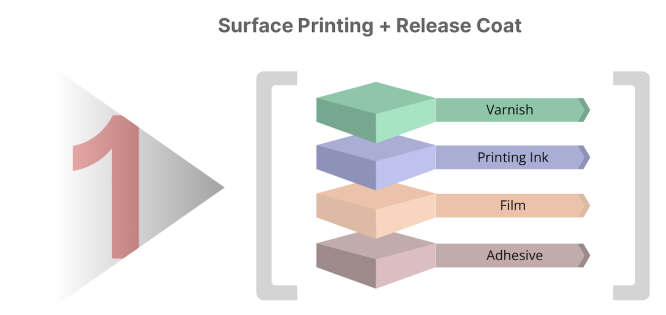

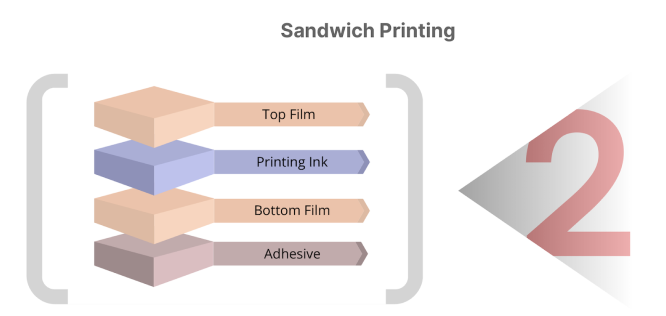

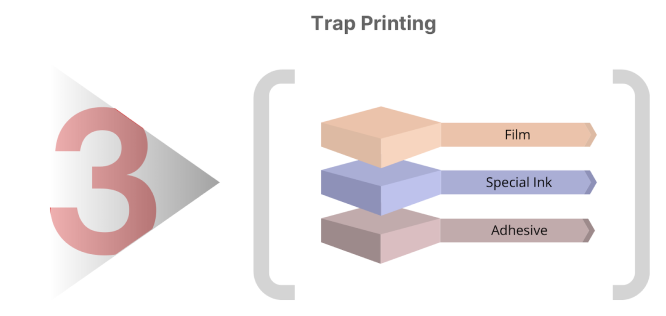

Printing

Wide-width Rotogravure Printing Press

Lamination

Wide-width Solvent-based Lamination Machine

ECOGEN, a specialty range of lamination PE films by Ecoplast Ltd., is engineered for superior adhesion, high-speed lamination, and excellent anti-static properties. Ideal for food, beverages, cosmetics, and personal care packaging, ECOGEN ensures reliable performance across various substrates.

Superior Adhesion | High-Speed Lamination | Durable Performance

Coating

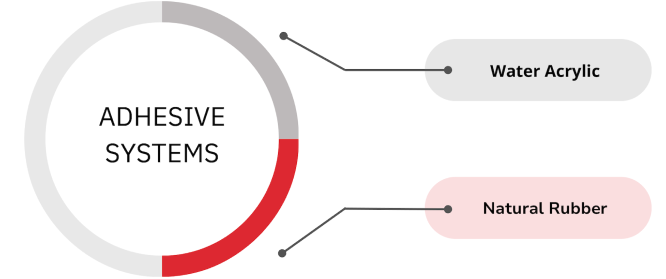

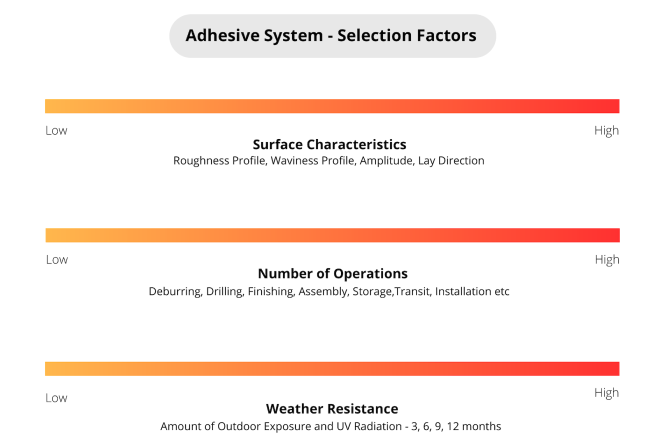

Precision adhesive coating machines fitted with various coating heads to handle diverse adhesive systems

and coat weights

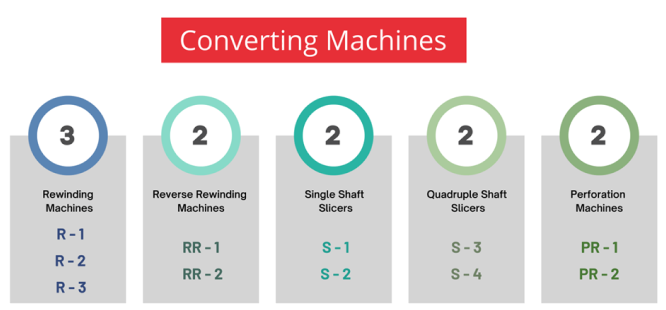

Converting

High-speed, Slitting, Slicing, Perforation and Rewinding Machines