ECOPRIME® - Pharma Applications

Pharma Applications

-

Crystal-Clear Transparency

Crystal-Clear Transparency

-

Smooth Coating Surface

Smooth Coating Surface

-

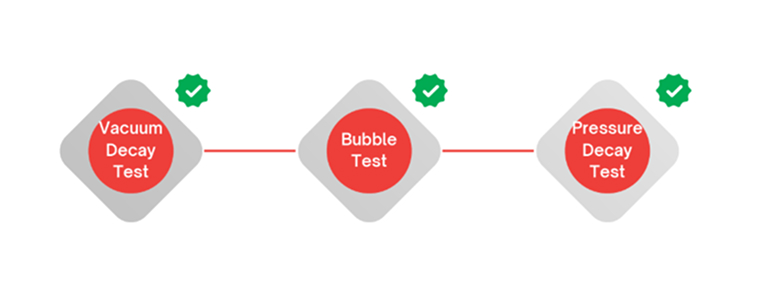

Pharmaceutical-Grade Compliance

Pharmaceutical-Grade Compliance

-

Superior Mechanical Strength

Superior Mechanical Strength

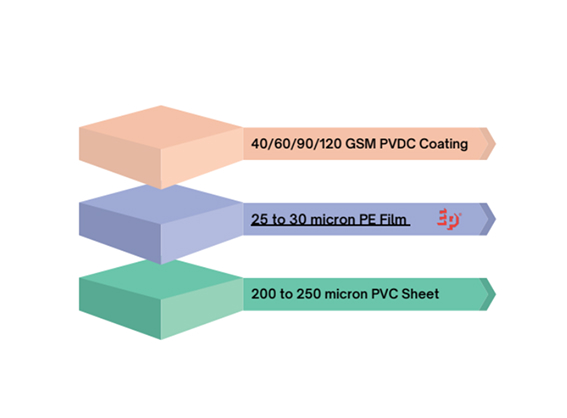

No blocking during unwinding of rolls

No blocking during unwinding of rolls Corona treated on one-side for easy lamination with PVC

Corona treated on one-side for easy lamination with PVC Adapted for excellent performance on a wide range of machines, line speeds, and dwell times

Adapted for excellent performance on a wide range of machines, line speeds, and dwell times Designed to work at a wide range of cavity forming temperatures

Designed to work at a wide range of cavity forming temperatures