Why Surface Protection Films Are Revolutionizing the Construction Industry

Surface Protection Films from Ecoplast Limited are transforming how the construction industry safeguards materials like marble, UPVC, glass facades, and HVAC vents. Discover their benefits and uses.

Introduction to Surface Protection Films

In the dynamic and ever-evolving world of construction, protecting high-value surfaces is critical. One of the most effective and innovative tools for this purpose is Surface Protection Films. These films are thin layers of polymer-based material—typically LDPE (Low-Density Polyethylene) or PVC—that temporarily cover surfaces during manufacturing, transport, storage, and installation.

Surface protection films are not only meant to shield materials from physical damage like scratches and scuffs but also from dust, dirt, UV exposure, paint splashes, and abrasions during construction activities. They play a huge role in ensuring that surfaces remain in pristine condition until project completion.

Main Construction Site Image

Construction site showing surface protection films applied to marble, UPVC windows, and HVAC vents, by Ecoplast Limited.

Benefits of Using Surface Protection Films in Construction

- Cost Savings: Repairs and replacements due to surface damage can inflate project budgets. Surface protection films eliminate this risk.

- Efficient Workflow: By keeping surfaces clean and undamaged, construction workers can work around them freely without concern, improving overall productivity.

- Aesthetic Integrity: Surfaces like marble and glass are sensitive to even the smallest blemish. These films help maintain their visual appeal until final handover.

- Environmental Advantage: Many modern films are recyclable, and by preventing wastage through damage, they contribute to sustainable practices.

Surface Protection for Marble and Natural Stone

Marble is prized for its beauty but is incredibly vulnerable to scratches, stains, and impact. Using protective film ensures:

- Safe transportation and installation

- Shielding from paint, adhesives, and dust

- Easy peel-off without leaving adhesive residue

Ecoplast’s protective films for marble come with anti-slip and UV-resistant properties, perfect for both indoor and outdoor settings.

Protecting Window and Door Panels

Window and door frames made of glass, aluminum, or wood are expensive and delicate. During installation, they’re exposed to risks like:

- Accidental scratches from tools

- Dust accumulation

- Paint overspray

By applying Ecoplast protection films, contractors can ensure frames and glass panes remain spotless. These films can be removed easily before handover, revealing surfaces as flawless as the day they arrived.

Protected Window

Close-up view of modern window panels covered in Ecoplast Limited’s branded surface protection films.

Surface Films for UPVC Fixtures and Frames

UPVC materials are popular for their durability and weather resistance, but they are prone to:

- Surface scuffing during handling

- Discoloration from prolonged UV exposure

- Chemical reactions from construction materials

Surface protection films help eliminate these threats. Ecoplast offers specially designed films for UPVC that preserve their glossy appearance and structural integrity.

Role of Protection Films in Vent and HVAC Installations

HVAC systems are crucial for indoor air quality, but open ducts and vents during construction can accumulate:

- Cement dust

- Paint mist

- Construction debris

Using surface protection films during the installation of HVAC components ensures cleanliness and hygiene while reducing post-installation cleaning.

Shielding Glass Facades During High-Rise Projects

Tall buildings with extensive glass exteriors are vulnerable during construction. Glass panels need:

- Protection from welding sparks, concrete spills, and dust

- Scratch-resistance during scaffolding work

- UV shielding from prolonged sun exposure

Ecoplast’s high-tack adhesive films are engineered for these applications, ensuring that the glass facade shines on completion day.

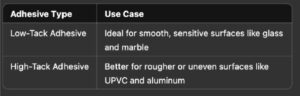

Different Types of Adhesives and Film Thickness Options

The right film depends on the surface and application. Options include:

Film Thickness:

Ranges from 30 microns to 120 microns depending on protection needs. Thicker films offer better impact resistance.

Easy Application and Removal Techniques

Installation is simple:

- Clean the surface

- Align the film using rollers or manual tools

- Smooth out air bubbles

Removal is even easier—just peel it off in one go without leaving behind sticky residue.

Customization and Branding Options for Builders

At Ecoplast Limited, we offer custom-printed films with:

- Your company logo

- Project name

- QR codes for traceability

This allows companies to build brand visibility even during the construction phase.

Case Studies: Real-Life Projects from Ecoplast Limited

- High-Rise in Mumbai: Used Ecoplast films on glass facade and marble interiors. Result: Zero post-installation damage.

- Hospital Construction in Pune: Protected all UPVC windows and vents with Ecoplast films. Client praised the clean handover process.

- Luxury Villa in Hyderabad: All marble flooring was shielded with surface films. Client saved ₹11.5 lakhs in repair costs.

Buyer’s Guide: Choosing the Right Film for Your Project

Checklist:

✅ Surface Type (marble, UPVC, etc.)

✅ Exposure to Sun or Chemicals

✅ Duration of Protection

✅ Residue-free Removal

✅ Branding Needs

Pro Tip: Call Ecoplast’s expert team for a personalized consultation.

Frequently Asked Questions (FAQs)

Q1: Can these films be used outdoors?

Yes, our UV-stable films are perfect for outdoor use and long durations.

Q2: Do they work on textured surfaces?

Absolutely. We offer high-tack variants for better grip on textured surfaces like UPVC.

Q3: How long can the film stay on the surface?

Depending on conditions, up to 6 months without degradation.

Q4: Will the film damage the surface when removed?

Not at all. Our films are engineered to peel off cleanly without residue.

Q5: Can I get films with my company’s logo?

Yes! We offer full branding options for contractors and developers.

Q6: Are these films eco-friendly?

Yes. Ecoplast’s films are recyclable and comply with sustainability standards.

Conclusion: Why Ecoplast Surface Protection Films Are a Smart Investment

Surface protection films are no longer a luxury—they’re a necessity in today’s high-stakes construction environment. From marble to HVAC vents, these films offer reliable, cost-effective, and eco-conscious solutions to keep your surfaces flawless.

At Ecoplast Limited, we combine innovation, quality, and customization to deliver surface protection solutions that meet your exact needs. Whether you’re working on a villa, hospital, or skyscraper—trust Ecoplast to protect your vision.

Ready to Protect Your Surfaces the Smart Way?

Don’t let scratches, stains, or dust compromise your project’s quality.

Choose Ecoplast Limited’s Surface Protection Films—designed for durability, performance, and eco-conscious construction.

👉 Contact us today for a free consultation or custom quote!

📧 Email: [email protected]

🌐 Website: www.ecoplastindia.com

contact us at: +91-22-2683 3452 / +91-22-2683 1403, or drop an email at: [email protected]