ECOPROTECT® - Surface Protection Films

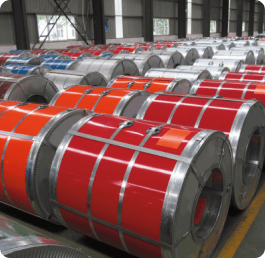

Pre-Coated Metals

Compatible with all coatings

Polyester

Polyester PUR

PUR PVDF

PVDF PVC Plastisol

PVC Plastisol

There are numerous risks of damage, scratches, and contamination throughout the production, storages, transit, and installation phases of your materials.

Our engineered protective films are tailored to preserve the integrity of your products.

Easy, uniform and quiet unwinding of film rolls.

Optimal adhesive strength is rapidly achieved as soon as the film is applied on the both sides.

Film does not lift or get removed during operations. It is resistant to various mechanical and thermal stresses.

Films have ideal puncture resistance, elongation and tensile strength properties. No fibers or strains visible after cutting.

Films come with UV radiation-blocking properties - protects against outdoor UV exposure of 3, 6, 9 and 12 months.

Easy, effortless, uniform, optimal peel-off strength - without tearing.

Zero risk of any residue (film or adhesive) left behind on the profile surface

| Product | ECOPROTECT® 230G-X | ECOPROTECT® 204G-X |

|---|---|---|

| Common Thickness (mic) | 50 | 50 |

| Common Color | Clear Transparent | Clear Transparent |

| Adhesive Type | Water Acrylic | Water Acrylic |

| Tensile Strength (gms/mm²) - MD | 19 - 23 | 17 - 22 |

| Tensile Strength (gms/mm²) - TD | 17 - 19 | 18 - 20 |

| Elongation (%) - MD | 600 - 800 | 500 - 700 |

| Elongation (%) - TD | 850 - 950 | 750 - 950 |

| Adhesive Value (gms/25mm) | 70 - 130 | 100 - 160 |

Discover our Surface Protection Films range for a variety of Industrial Applications

Pre-Coated Metals